Mass-Customizing

End-to-End solution for manufactureers and suppliers of “Mass-Customizing” und “Fashion on Demand”

Initial situation

Did you know that millions of euros are wasted every year by producing clothes that nobody buys? Production based on estimates and assumptions, months before the sale takes place, causes 10% overproduction that is neither listed in retail stores nor online – but is directly destroyed again.

New business model: Mass-customization

It doesn’t have to be this way. There is a better solution: “Pod – Pattern on Demand®”. With this innovative platform, you can adapt your production to demand by putting your customers at the center. You can give them the satisfaction of receiving a unique and personalized product made just for them.

Act sustainably

With “Pod – Pattern on Demand®” you save money, time and resources by producing only what you sell. You reduce your inventory, your energy consumption and your CO2 footprint. You increase your profitability, your customer loyalty and your competitiveness. “Pod – Pattern on Demand®” is the future of the fashion industry. The platform supports sustainable business models for modern companies.

Contact us today and find out how you can become part of this revolution.

News and good to know

Would you like to be automatically informed about news from our company in the future? Then subscribe to our newsletter and let us know which topics you are interested in.

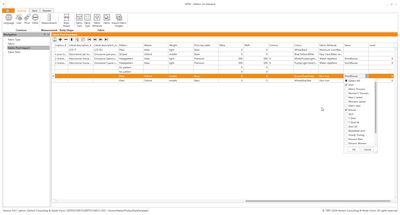

Fabric and material – Import

We’ve just made it easy for you to capture new fabrics or materials!

Fabric and material – Import

We’ve just made it easy for you to capture new fabrics or materials!

Here you will find the most important new features of our platform, broken down by individual applications.

2021

- New configurator

- Plugin for WordPress and WooCommerce

2022

- API-documentation

- Body-Shape calculation

2023

- Integration of a new bestfit-methode

- Body-Shape enhancement

- several Extensions

2024

- Extension of the configuration to transfer further data to 4-Manufacture.

- Switch to a new server platform with the latest software release.

- Switch to a new FTP connection to increase security.

2021

- New command SBINFO REGMARKS

- New command PIECE SETANNO

- New command SBINFO SETARTANNO

- Export 3D-folderlist as CSV-file

- fabric-rolls export as CSV/PDF

2022

- Body-Shape configuration

- Various smaller extensions

2023

- New version with integration of dark/light mode and new icons

- Integration of the AI-supported translation service from DeepL

- Various minor improvements

2024

- New user role for data protection tasks to manage.

- New option for entering materials and fabrics in MTM.

Now via a dynamic table and import function. - Comments and notes can now also be added to the commands.

- Integration of Size_1 (GRAFIS) into our pod system.

- And many other minor improvements in handling.

2021

- CSV import from Shopify via the handles

- Multi-Order Layplans:

Combining several orders with the same fabric into one layplan – with assignment to a fabric bale, so that the fabric width and indentation values can be incorporated into the layplan accordingly.

2022

- Extended control for multi-order markers

- Time-controlled mode extended

2023

- New version with integration of dark/light mode and new icons

- Built-in data protection functions

- Create a style with all standard sizes

- Product data function

- Further Same-Layplan Methodology

2024

- Improvements and extensions in the handling of order measurement charts.

- It is now also possible to restore ‘deleted’ orders via the privacy settings.

- Extensions in the ‘Same Layer Pattern’ area.

- User-dependent sorting of order views.

- And many more minor improvements and extensions.

2021

- New AMP module based on multi-order layouts

2023

- New version with integration of dark/light mode and new icons

2024

- Minor improvements

Your Customer can act as a Co-Designer!

With “pod – Pattern on Demand®”, you are able to offer your customers the opportunity to co-design their personal clothing style in terms of cut, shape, colour and fabric. Your customer thus becomes a co-designer and receives their garment according to their individual measurements. You can now confidently face the major challenge of how the order can be reliably, quickly and easily converted into a corresponding pattern or pattern layer, which also remains reproducible for re-orders!

This is because the platform we have developed is designed to transfer customised made-to-measure orders with a batch size of one piece fully automatically from a web shop order to a cutting pattern. This allows you to process your customised orders efficiently and with a high degree of reliability.

Our brochure

You can download our brochure on the “pod-Pattern on Demand” platform via the following link. (June 2022)

“What we particularly like about “pod – Pattern on Demand®” is that it is very easy to use, which also results in a quick learning curve for users. Compared to our previous methodology, we save +/- 50% in time, from order entry to finished cutting. The possibility to work with individual measurements as well as to store standardized models helps us to work even more efficiently. We can rely on the fact that new and repeat orders can be carried out quickly – and are always 100% size conform. The support provided by Gertsch Consulting is competent, fast, friendly, good and informative and reflects a high degree of helpfulness. Questions or problems that arise are usually solved in the shortest possible time.”

“What I find ingenious about “pod – Pattern on Demand®” is that it enables me to completely control pattern creation with GRAFIS® from outside. It allows to make individual customized orders from the store available to a production facility in the shortest possible time. The manufacturer receives all cutting data and production documents fully automatically within a few minutes and can start production immediately. In addition, the price/performance ratio is very good. The support is super and made it possible to implement individual software adaptations and extensions tailored to my company´s demands. I am very satisfied with the platform and can truely recommend it!”

Modular design

Depending on how you have structured your business model (B2B / B2C), you can use our platform accordingly! The modular range of functions and the scalability of the platform make it a loyal companion from small start-ups to large companies.

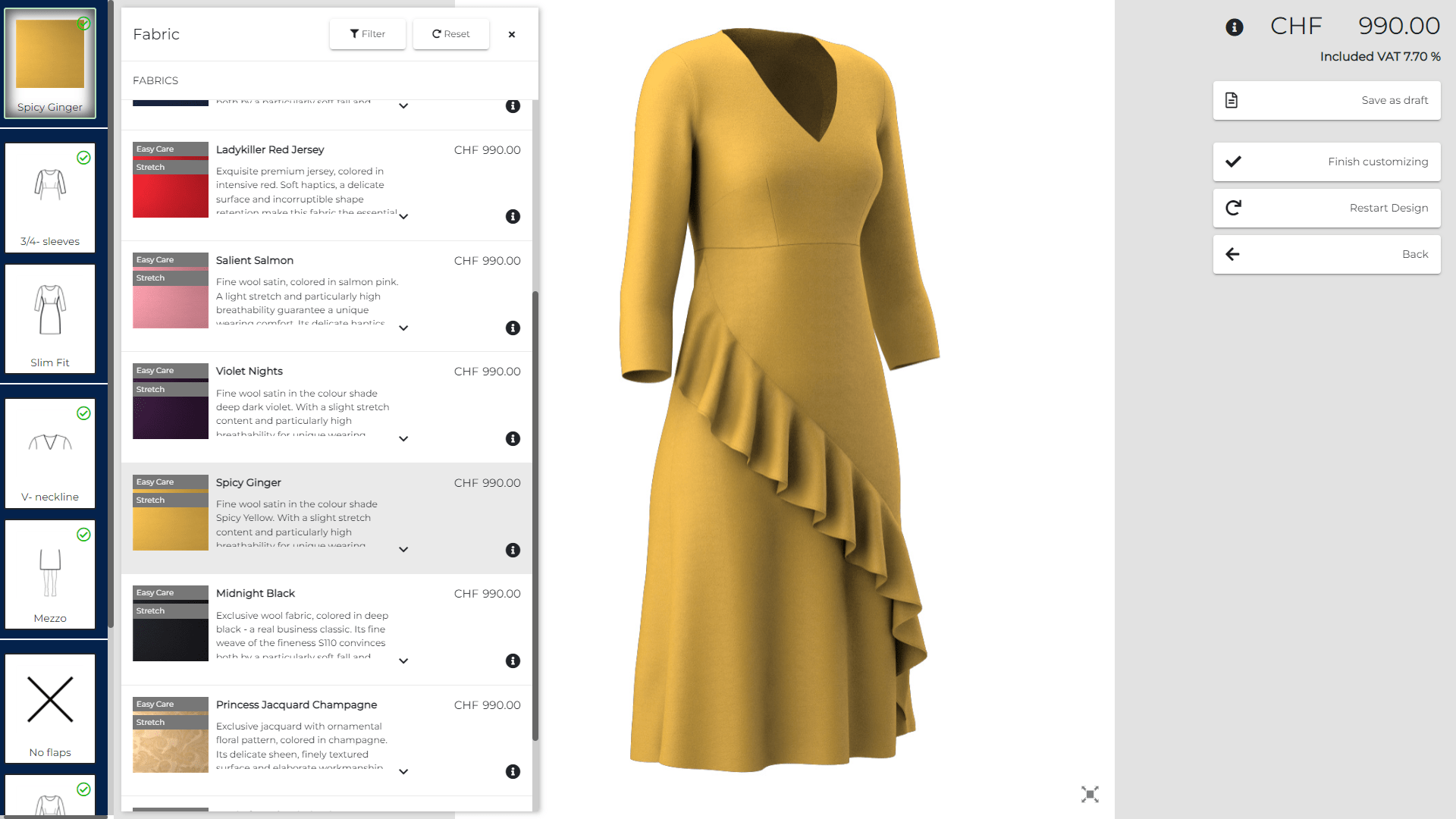

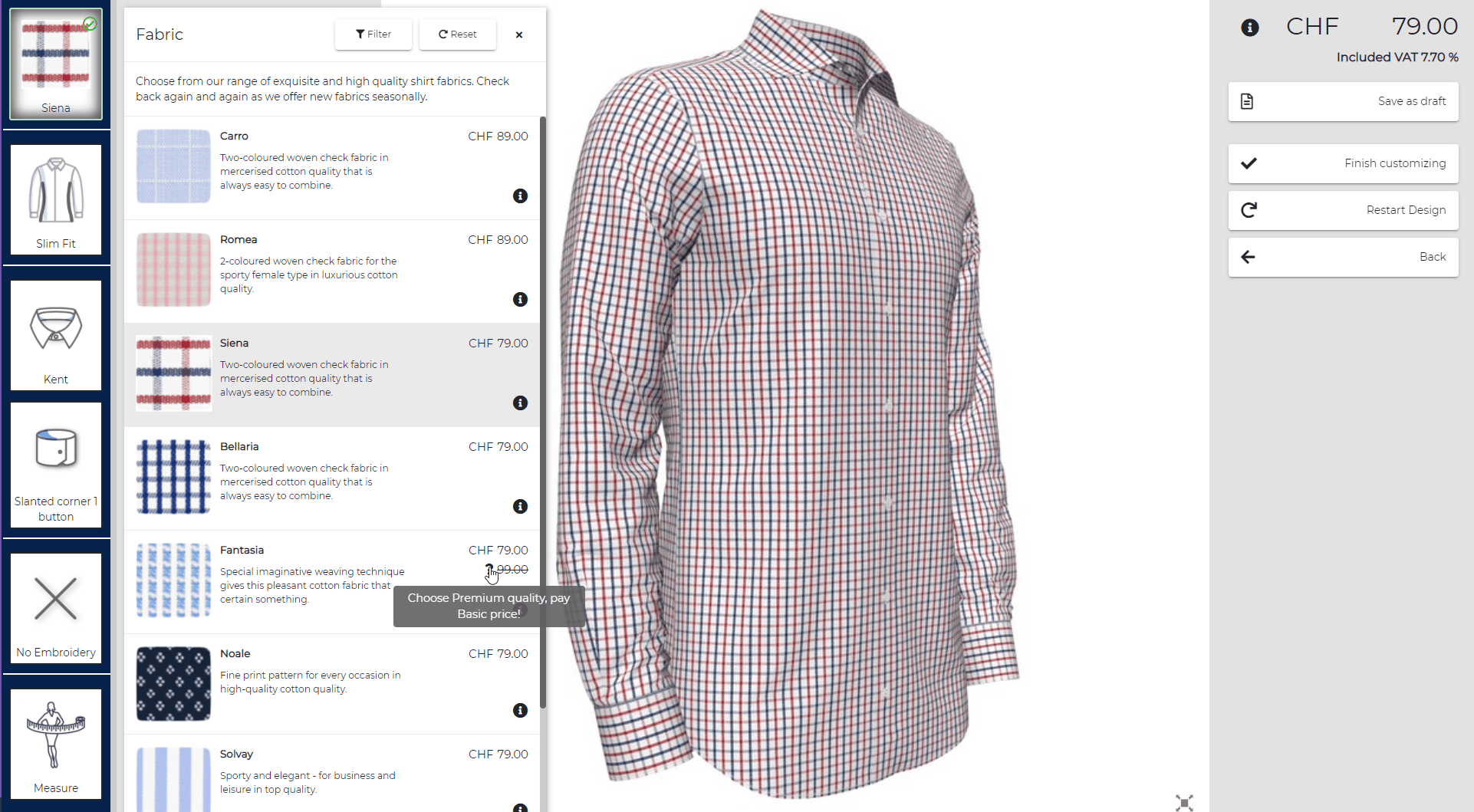

Customization

Offer your customers a unique user experience

Configurator with Plugin for

WordPress / WooCommerce

Our new configurator guides your customers intuitively and safely through the ordering process! The integrated visualization – also in 3D – supports the customer in his decisions. The responsive design ensures a correspondingly good user experience on all end devices.

The plugin we developed for WordPress / WooCommerce offers you seamless integration of our configurator into the store.

The plugin is configurable, whether you operate a B2C or B2B webshop.

You can see how our plugin and the configurator work here: “Fashion on Demand”.”Fashion on Demand“.

Then select in the menu above:

- Customize Shirt for a 2D representation of a shirt

- Customize Dress for a rotatable 3D representation of a dress (visualization created by Tronog)

- Customize Shirt 3D for a 3D representation of a shirt with the output of VStitcher from Browzwear

Alternatively, you can of course create your own webshop and import and process the orders via XML interface in our “pod – Patten on Demand®”.

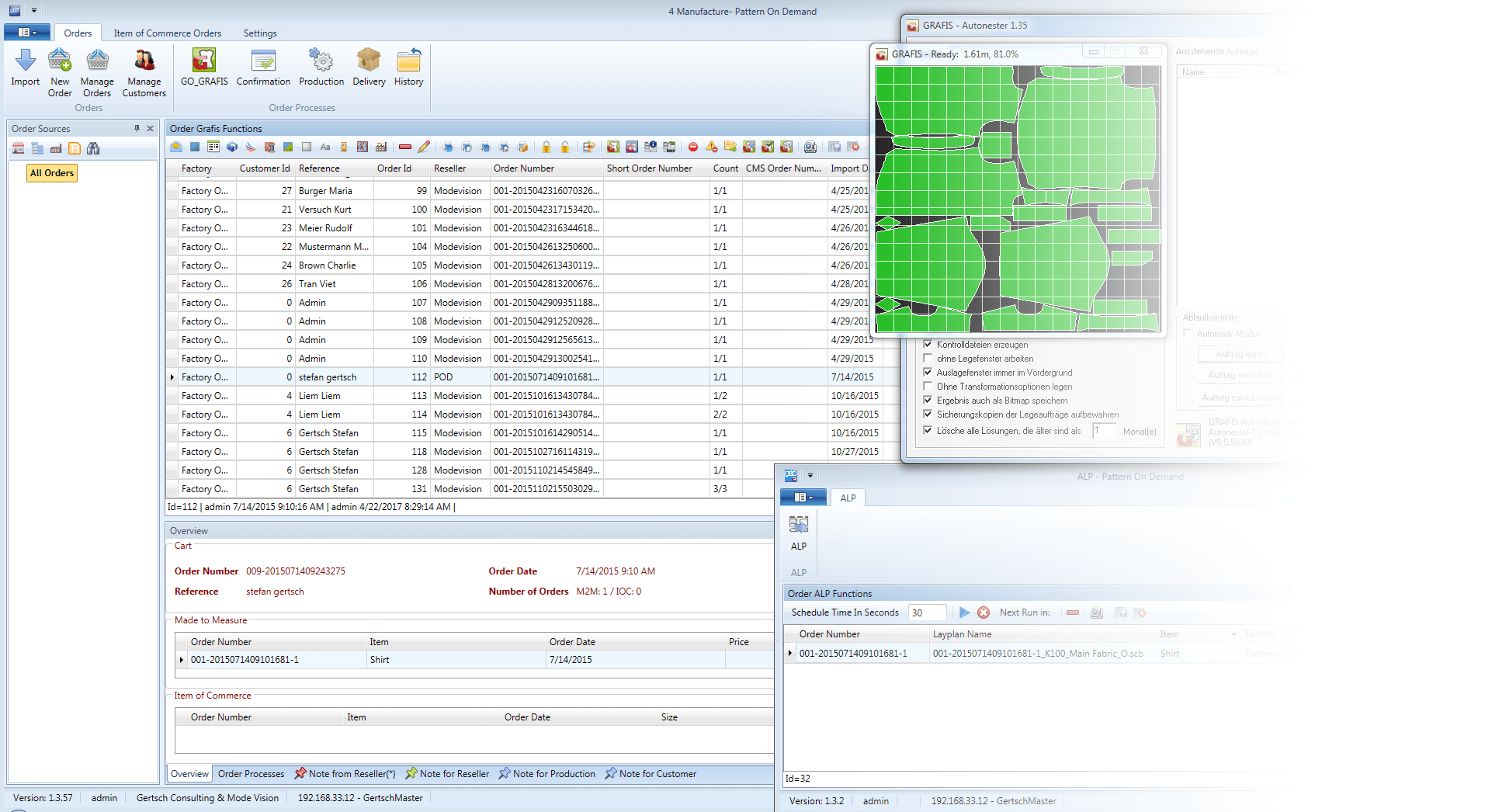

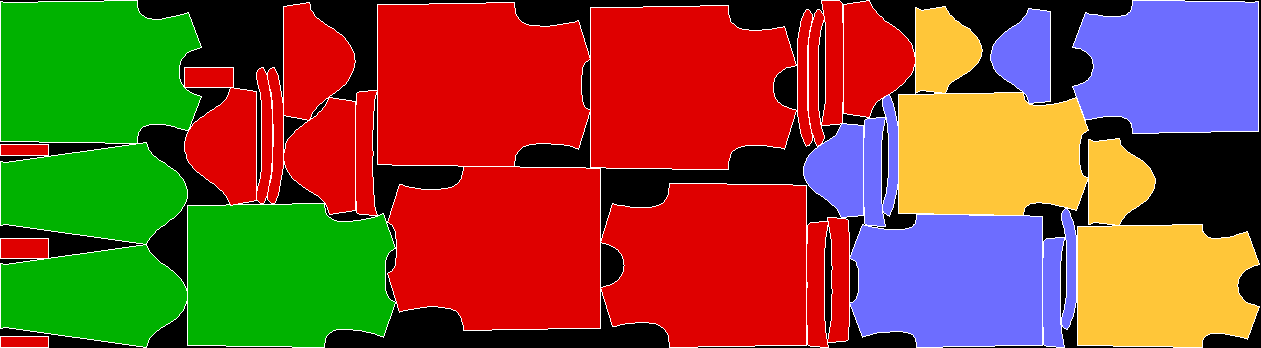

CAD-Control

Fully automatic marker-making

Enjoy the security of knowing that your Made-to-Measure orders will be processed reliably!

The fast and, above all, fully automated processing of web store measurement orders is the core task of our platform. The patterns or pattern layouts are created in the GRAFIS® CAD software, which demonstrates its particular strengths in the production of made-to-measure patterns and in made-to-measure manufacturing. The models are controlled by body measurements and parameters and automated processes are initiated externally by “pod – Patten on Demand®”.

Depending on your requirements and the number of orders to be processed per day, we offer various expansion stages of the software. This gives you your customized “pod – Patten on Demand®” platform! For small companies, the software offers the option of entering custom orders manually, even without a web store, so that they can then be processed automatically.

The platform now also supports the option of multi-order cutting patterns, so that several orders with the same fabric can be combined into one cutting pattern.

Production

Production papers and production tracking

The corresponding output for your production

Based on your production requirements, the cutting patterns are output in the appropriate formats and information. Corresponding accompanying documents such as production orders or overviews help production to process the orders.

Our platform also accompanies your orders through production so that you are always in the picture. Production documents and production tracking are further functionalities of our software.

In addition, all order data with the material consumption achieved can be made accessible to your ERP software via a transfer database.

Advantages and benefits

- Supports sustainable business models

- Supports mass customizing

- Production and fashion “on demand”

- Emotional connection of your customer as a co-designer to your brand and company (customer experience)

- Fast and secure processing of individualized made-to-measure orders

- Knowledge and tailoring sovereignty remain in your company

- Saving of time and material

- Reproducibility of orders

- Easy to use

- Multilingual, configurable and scalable

- Ready for use

“In the 21st century, sustainability is no longer a question of whether, but of HOW. Mass customization, the core DNA of the PoD system, is a promising approach to provide unique products in a resource-saving and scalable way for the customer.” “Interdisciplinarity, enthusiasm, highest expertise. And this in both technology and product perspective. We are very grateful to have had the opportunity to realize our Fashion Configurator at SANOGE together with Stefan Gertsch and his team. The result: a technological innovation that delivers real added value for the customer, enables sustainable business models and represents a unique selling proposition in the market.” “Customer Experience: the key word for success in the market in the 21st century. Customers and clients are no longer just looking for products, but experiences. This is where PoD’s system of mass customization comes into play. If you want to offer your customers something unique, you have to make them the center of attention. And what better way to do that than with the help of a maximally personalizable fashion configurator.” “How can we break the rules of the fashion industry and contribute to an ecological, socially oriented, sustainable future? Instead of high inventories and overproduction, PoD uses mass customization to focus on ‘production on demand’. Flexible, scalable and customer-oriented. Only what is actually in demand is produced. This conserves resources and enables production at the point of demand: urban manufacturing.”

GRAFIS CAD Clothing construction

The GRAFIS CAD system provides you with innovative software for the design of clothing and technical textiles, combining the classic approach to creating professional patterns for the clothing industry with the advantages of digital, effective and intuitive working.

In contrast to other CAD systems, GRAFIS CAD garment construction has the advantage of the construction principle on your side. Each of your steps is documented in a protocol and can be used again and again with different (body or finished) measurement charts or pattern settings to give you maximum control over your pattern development.

Further and detailed information on GRAFIS can be found directly under the following manufacturer link: GRAFIS

GRAFIS brochure

You can download the GRAFIS brochure via the following link.

API interface

We have a corresponding API interface for your own webshop integration with configurator, which we use ourselves for our plugin for WordPress and WooCommerce.

The documentation is in English.

References “pod – Pattern on Demand®”

Our customers offer high-quality and individualized clothing and are active in the areas of sports, women’s and men’s outerwear and thobs.

Do you have any questions about our product or services? Would you like a non-binding demonstration of our platform? Please contact us, we will be happy to advise you!

Contact form

Office

Mühlethalstrasse 79 CH-4800 Zofingen

Phone

0041 – (0)62 751 26 01

Follow us on Linkedin

Gertsch Consulting

Here you will find our office!